Understanding the Versatility of the Best Carton Taping Machines: Features and Applications for Diverse Products

In the fast-paced world of packaging and logistics, the Carton Taping Machine stands out as an essential tool for businesses seeking efficiency and reliability in their operations. These machines have evolved significantly, offering a range of features that cater to the diverse needs of various industries. From enhancing operational speed to ensuring product safety during transit, the versatility of carton taping machines is unparalleled. In this blog, we will delve into the key features and advantages of modern carton taping machines, exploring their applications across different product types. By understanding their capabilities, businesses can make informed decisions that align with industry production standards, ultimately optimizing their packaging processes and improving overall efficiency.

Exploring the Key Features of Top Carton Taping Machines for Optimal Performance

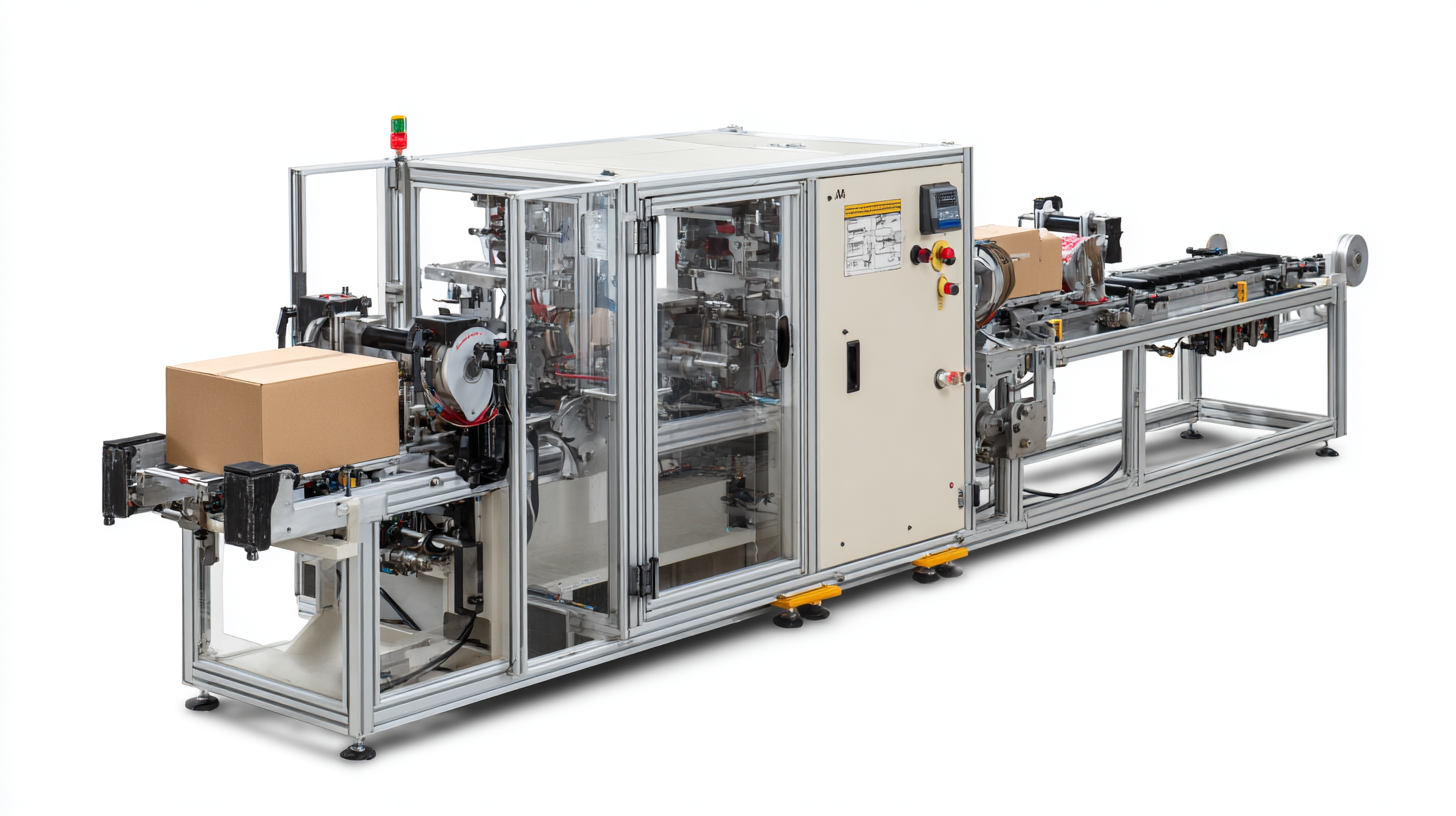

When it comes to efficient packaging, the choice of carton taping machines significantly impacts operational productivity. The best machines feature adjustable tape tension control, allowing users to customize the application based on the weight and size of the cartons. This flexibility ensures secure sealing while minimizing tape waste, which is important for cost management. Additionally, many top models come equipped with automatic tape dispensing mechanisms that streamline the packing process, offering both speed and precision.

Durability is another vital aspect that defines high-quality carton taping machines. Robust construction materials and advanced engineering contribute to machines that withstand the rigors of industrial use. Enhanced features such as easy-to-use controls, quick-change tape rolls, and integrated safety measures further improve functionality while ensuring operator safety. Furthermore, the versatility of these machines extends beyond traditional carton sealing; they can accommodate various products, from fragile items to heavy goods, making them invaluable in diverse packaging environments.

Common Industry Challenges in Choosing the Right Carton Taping Equipment

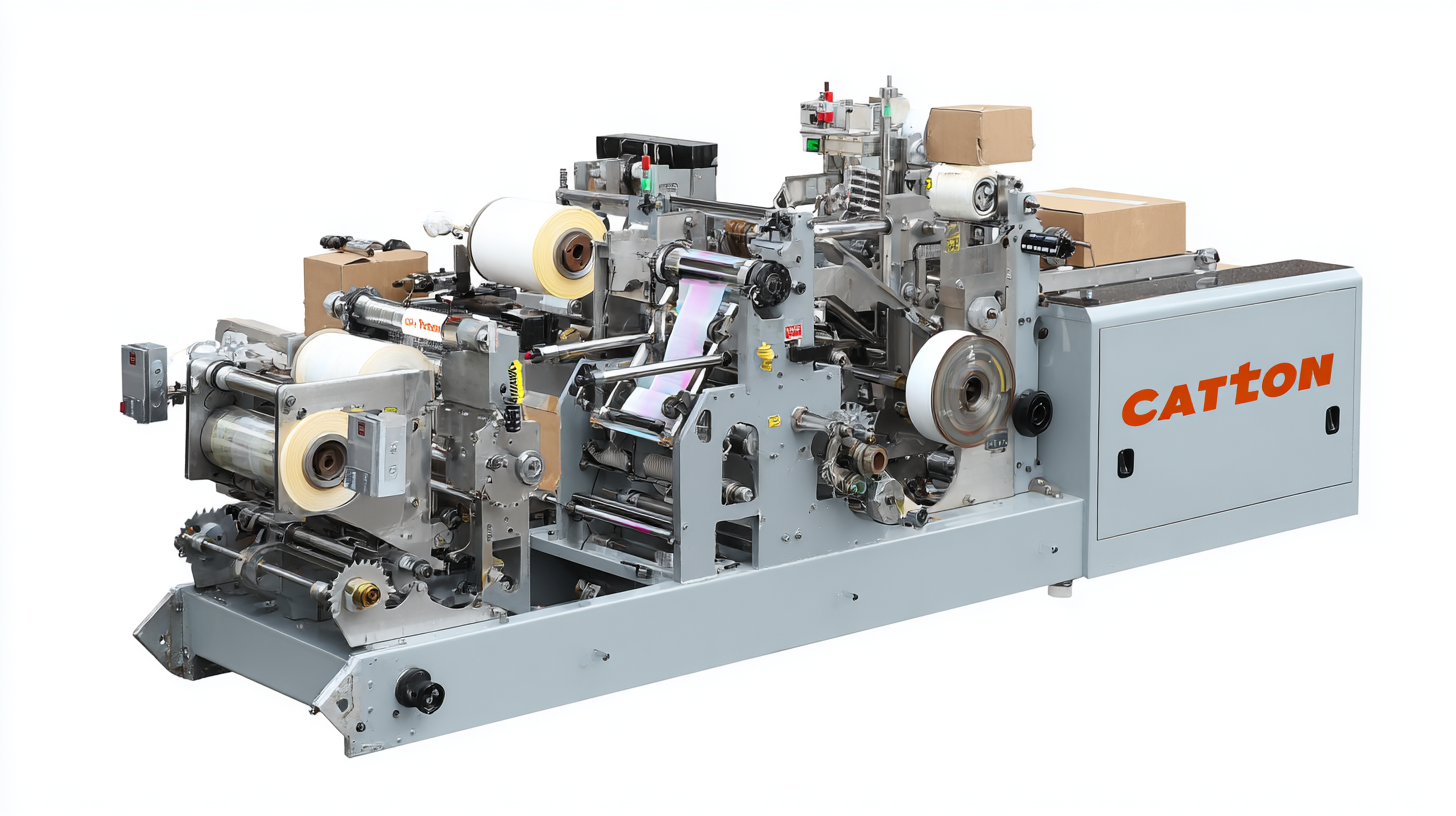

When selecting the right carton taping equipment, industries face several common challenges that can significantly affect their packaging efficiency and product integrity. A recent report by the Packaging Machinery Manufacturers Institute (PMMI) highlights that nearly 60% of packaging errors are linked to inadequate machinery choices. This underscores the importance of understanding the specific needs of a production line before making a purchase. Factors such as the type of products being packaged, throughput requirements, and facility space constraints play crucial roles in determining the most suitable carton taping machines.

Another critical issue is the adaptability of taping machines to various carton sizes and materials. According to a survey conducted by the Association for Packaging and Processing Technologies (PMMI), about 70% of manufacturers struggle with equipment that cannot accommodate fluctuating product dimensions, leading to increased downtime and maintenance costs. Therefore, investing in versatile taping solutions, which can handle a wide range of packaging formats, is essential. By choosing the right equipment, companies can not only streamline their operations but also improve their overall packaging quality and reduce waste.

The Role of Carton Taping Machines in Enhancing Packaging Efficiency

Carton taping machines play a crucial role in enhancing packaging efficiency across various industries. By automating the sealing process, these machines significantly reduce the time and labor required to secure cartons, enabling businesses to streamline their operations. In high-volume production environments, the speed and reliability of carton taping machines can greatly mitigate the risk of human error, ensuring that packages are consistently sealed and ready for shipment.

Moreover, the versatility of carton taping machines allows them to cater to diverse products and packaging needs. Whether dealing with small, light items or larger, heavier boxes, these machines can be adjusted to accommodate different carton sizes and materials. This adaptability not only enhances efficiency but also minimizes waste, as businesses can utilize the same machine for multiple packaging requirements. As a result, incorporating carton taping machines into the packaging process is a strategic investment that can lead to improved productivity and cost savings over time.

Understanding the Versatility of the Best Carton Taping Machines: Features and Applications for Diverse Products

| Feature | Description | Application | Efficiency Improvement (%) |

|---|---|---|---|

| Automatic Taping | Automatically applies tape to cartons, reducing manual labor. | E-commerce Packaging | 40% |

| Adjustable Tape Width | Accommodates various tape widths for different carton sizes. | Industrial Packaging | 30% |

| Ergonomic Design | Designed to minimize strain and provide comfort during use. | Retail Packaging | 20% |

| Speed Control | Controls the speed of taping to reduce wastage. | Food & Beverage Packaging | 25% |

| Electrical/Manual Operation | Can operate electronically or manually according to needs. | Cosmetics Packaging | 35% |

Applications of Taping Machines Across Various Industries and Product Types

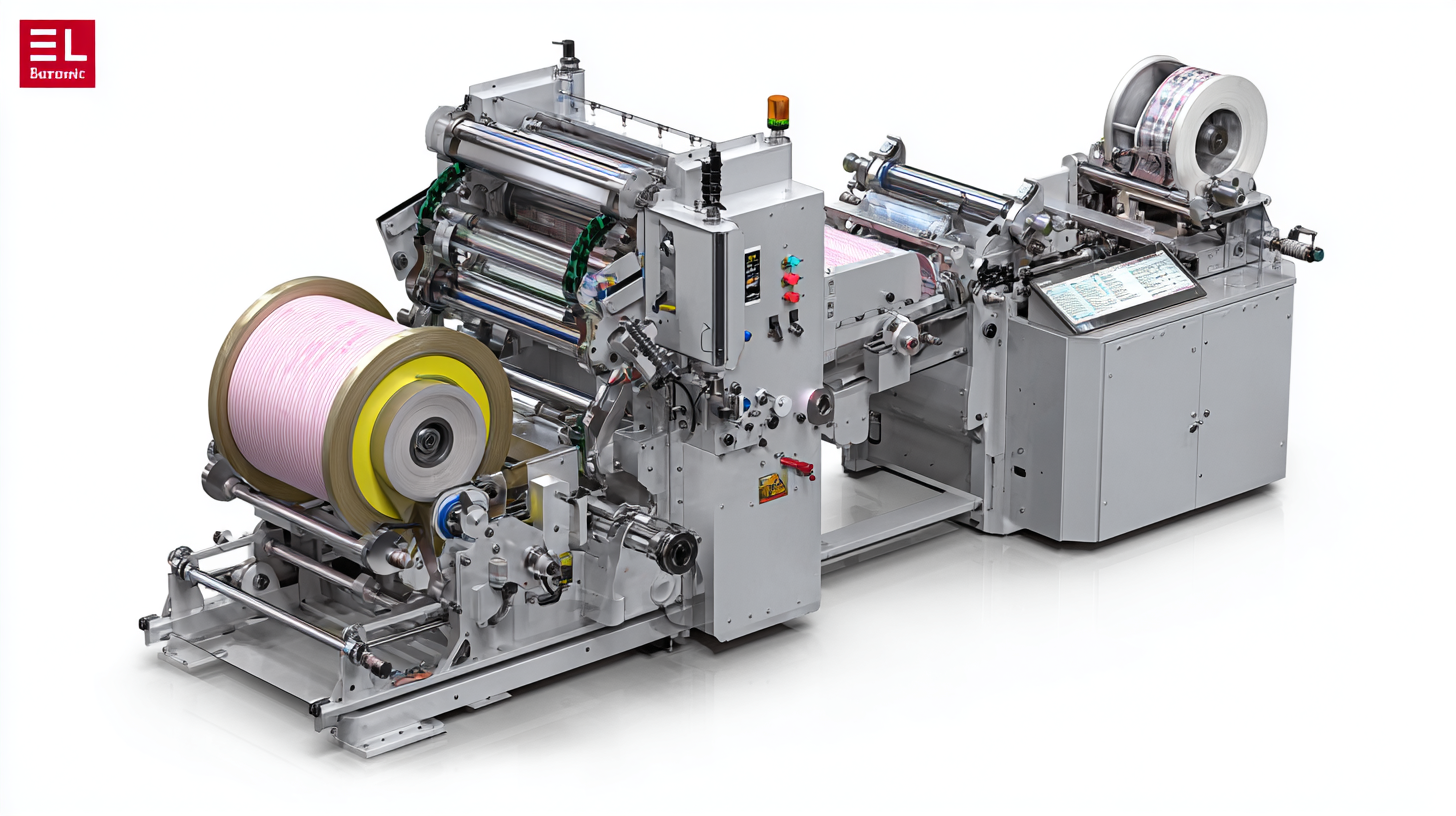

Understanding the versatility of carton taping machines is crucial for various industries, as their applications span across packaging and product protection. For instance, the global duct tape market is projected to grow significantly, reaching a size of $6.85 billion by 2030. This growth highlights the increasing reliance on effective sealing solutions in industrial applications. Taping machines not only streamline packaging processes but also enhance product integrity, making them invaluable in sectors such as manufacturing, logistics, and retail.

Incorporating advanced features like adjustable tape tension and automatic feeding mechanisms, modern taping machines cater to diverse product types, from food containers to electronics. The reflective tape market is also on the rise, driven by safety regulations and innovations in material types that enhance visibility in various environments. Utilizing these machines can mitigate operational costs and improve efficiency, providing an edge in competitive markets.

**Tips:**

1. When selecting a taping machine, consider the material types and their compatibility with your product requirements to ensure optimal performance.

2. Regular maintenance and calibration of taping machines can significantly extend their longevity and functionality, preventing costly downtimes.

Future Trends in Carton Taping Technology and Their Impact on Productivity

The evolution of carton taping technology is substantially influencing productivity across various industries. As manufacturers seek to streamline operations, advanced tape machines are being introduced with features like automatic sealing, adjustable tension, and user-friendly interfaces. These innovations not only enhance speed but also ensure secure packaging, which is critical for maintaining product integrity during transit.

Tip: When selecting a carton taping machine, consider the variety of products being packaged. Machines equipped with adjustable settings can adapt to different sizes and weights, ensuring versatility and efficiency.

Looking towards the future, the integration of smart technology in carton taping machines is on the rise. Automation and AI-enabled systems are likely to drive further improvements, allowing for predictive maintenance and real-time monitoring. This will enable businesses to minimize downtime and maximize throughput, ultimately leading to enhanced operational efficiency.

Tip: Regularly assess your taping machine’s performance through monitoring systems. This can help identify potential issues before they become costly problems, further optimizing production workflow.