Understanding the Role of Palletizer Machines in Modern Manufacturing Efficiency

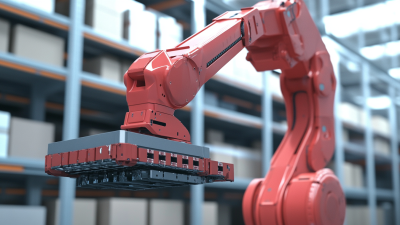

In the competitive landscape of modern manufacturing, efficiency is paramount, and one key player in achieving this is the Palletizer Machine. These machines streamline the process of stacking and organizing products for shipping, minimizing manual labor and reducing the risk of errors that can arise from human intervention. As industries strive to optimize their operations, understanding the intricacies of how a Palletizer Machine works becomes essential. This guide will delve into the functionality of these machines, their benefits in terms of time and cost savings, and how they can be integrated into various manufacturing processes. By unlocking the potential of palletizing technology, manufacturers can significantly enhance productivity and maintain a competitive edge in their respective markets.

How to Select the Right Palletizer Machine for Your Manufacturing Needs

When it comes to enhancing manufacturing efficiency, selecting the right palletizer machine is crucial. According to a recent report by Grand View Research, the global palletizing equipment market is projected to reach $3.2 billion by 2025, driven by increasing automation in various industries. Companies need to assess their specific production requirements, such as throughput rates and product types, to make an informed decision. For instance, traditional palletizers, which work at speeds of up to 20 cases per minute, may suffice for smaller operations, while high-speed models can handle over 100 cases per minute, making them ideal for large-scale manufacturing environments.

Furthermore, factors such as the type of packaging (bagged, boxed, or bottled) play a significant role in the selection process. A study by Future Market Insights indicates that robotic palletizers are gaining traction, as they offer flexibility and can be easily reconfigured for different products without extensive downtime. Integrating technologies such as vision systems for accurate product placement can also enhance the efficiency and effectiveness of palletizing processes. By understanding these considerations and industry trends, manufacturers can choose a palletizer that meets their operational goals and contributes to overall productivity.

How to Integrate Palletizer Machines into Existing Production Lines

Integrating palletizer machines into existing production lines is a strategic move that can significantly enhance operational efficiency. To begin with, it’s essential to assess the current workflow and identify areas where automation can make a positive impact. Conducting a thorough analysis of the production line will help determine the optimal placement of the palletizer, ensuring that it complements existing machinery and processes without causing disruption.

Once the position of the palletizer is established, the next step involves selecting the right model that aligns with the production volume and type of products being handled. Customization may be necessary to ensure a seamless fit with other equipment. Additionally, proper training for operators and maintenance staff is crucial. This ensures that everyone involved is familiar with the new system, enabling them to troubleshoot any issues that may arise and maximize the benefits of the new technology. With careful planning and execution, integrating palletizer machines can streamline operations, reduce labor costs, and improve overall productivity.

How to Optimize Warehouse Space with Efficient Palletizing Solutions

In the fast-paced world of modern manufacturing, optimizing warehouse space has become a critical factor for enhancing efficiency. Efficient palletizing solutions play a pivotal role in this optimization process. According to a report by the Material Handling Industry of America, effective palletizing can reduce labor costs by up to 25% and increase storage density by approximately 30%. This significant improvement allows manufacturers to allocate resources more effectively, ultimately boosting overall productivity.

Automated palletizer machines are leading the charge in warehouse space optimization. These machines not only streamline the packing and shipping process but also facilitate a more organized warehouse layout. For instance, companies that implement robotic palletizers report a reduction in operational errors by up to 40%, significantly improving warehouse workflow and space utilization. Furthermore, a study from Automate shows that manufacturers adopting advanced palletizing technologies can experience a payback period of less than two years, highlighting the financial benefits of incorporating these systems into their operations. By investing in efficient palletizing solutions, companies can make the best use of their warehouse space while improving their competitive edge in the market.

How to Maintain and Troubleshoot Palletizer Machines for Longevity

Palletizer machines play a crucial role in enhancing modern manufacturing efficiency by automating the stacking and organizing of products for shipment. As industries face increasing pressure to optimize their production processes, maintaining these machines is essential for ensuring operational longevity. Regular maintenance checks can significantly reduce downtime and repair costs, as improper handling or neglect can lead to mechanical failures. According to industry reports, a well-maintained palletizing system can achieve up to 95% efficiency in throughput, showcasing the importance of routine inspections and immediate troubleshooting.

Troubleshooting palletizers involves understanding common issues such as misalignment, software glitches, and mechanical wear. Industry experts recommend adhering to a proactive maintenance schedule that includes routine cleaning, parts lubrication, and software updates. Additionally, data analytics can play a vital role in predictive maintenance, allowing manufacturers to identify potential problems before they escalate. Reports indicate that companies that invest in technology-driven maintenance practices can see up to a 30% reduction in operational disruptions, underscoring the significance of establishing a robust maintenance framework for palletizer machines.

How to Measure the Impact of Palletizer Machines on Production Efficiency

Palletizer machines play a crucial role in enhancing production efficiency within modern manufacturing environments. As warehouses navigate challenges such as labor shortages and the increasing demands of diverse inventory, these automated systems streamline the palletizing and depalletizing processes, ultimately boosting output. The integration of such technologies not only lifts productivity levels but also adapts to a growing portfolio of stock-keeping units (SKUs), facilitating smoother operations.

To effectively measure the impact of palletizer machines on production efficiency, it's essential to consider various factors. One key approach is analyzing the reduction in labor costs and time savings realized through automation. Furthermore, assessing changes in throughput rates post-implementation can provide valuable insights into performance improvements.

Tips: Regularly evaluate production metrics before and after the deployment of palletizer systems to track progress. Additionally, investing in training for staff to work alongside automated technologies ensures a seamless integration into existing workflows. This synergy between human and machine can further elevate efficiency and flexibility in manufacturing operations.

Related Posts

-

The Future of Best Automatic Palletizer Machines Transforming Logistics Automation

-

The Future of Automated Solutions: Elevating Efficiency with the Best Auto Palletizer

-

Understanding the Impact of Automated Case Sealers on Packaging Efficiency and Cost Reduction

-

How to Select the Right Carton Taping Machine for Your Business Needs

-

Understanding the Versatility of the Best Carton Taping Machines: Features and Applications for Diverse Products

-

Mastering Precision in Automatic Box Taping Machines Made in China for Global Excellence