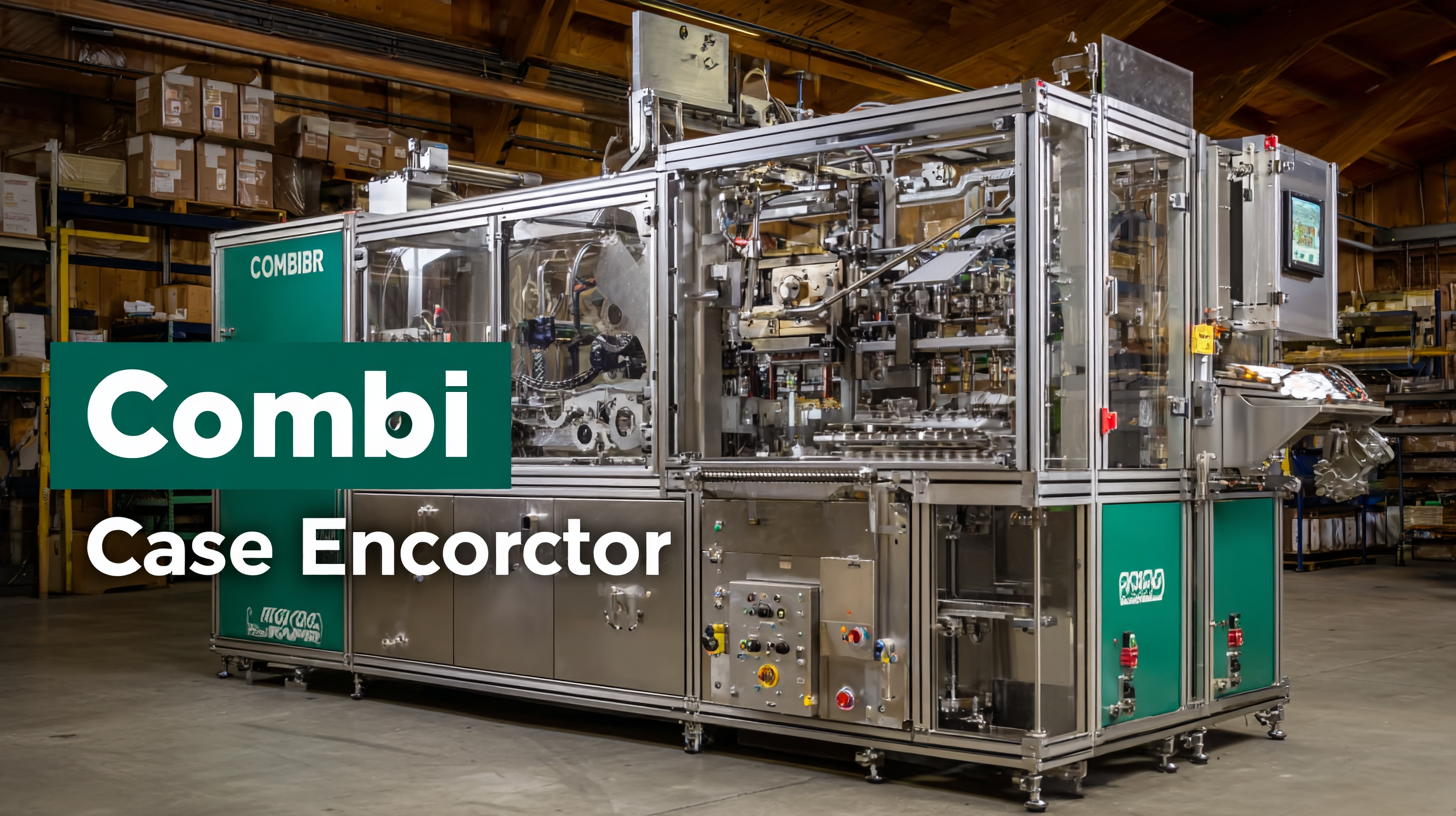

Top Strategies for Maximizing Efficiency with Best Combi Case Erector Solutions

In today's fast-paced manufacturing environment, the demand for efficiency and reliability is higher than ever, particularly in the packaging sector. According to industry reports, optimizing packaging processes can boost productivity by up to 30%, with automated solutions like the Combi Case Erector playing a critical role in this transformation. These machines not only streamline the erection of cases but also reduce labor costs and minimize material waste. A robust after-sales service is integral to maintaining operational efficiency, as it ensures that equipment is running at peak performance, thus controlling repair expenses over time. Additionally, adopting best practices in maintenance can lead to a significant reduction in downtime, allowing businesses to meet production targets consistently. This blog will explore top strategies for maximizing efficiency with Combi Case Erectors, highlighting the advantages of superior after-sales service and effective maintenance solutions.

Benefits of Comprehensive After-Sales Service for Combi Case Erectors

In the realm of combi case erecting solutions, after-sales service plays a critical role in maximizing operational efficiency and ensuring sustained performance. Recent reports indicate that manufacturers integrating comprehensive after-sales services have seen up to a 25% increase in customer retention, underscoring the significance of ongoing support in a competitive market. This tailored service not only helps in addressing immediate technical issues but also fosters long-term relationships, leading to repeat business opportunities.

Tips for Maximizing After-Sales Efficiency:

2. Real-time Monitoring: Implement predictive maintenance solutions that utilize real-time data to anticipate issues before they escalate, enhancing equipment reliability.

Moreover, as industries undergo digital transformation, the integration of AI in after-sales services is becoming prominent. Companies utilizing advanced analytics for customer feedback have reported a 30% improvement in their service responsiveness, proving that a proactive approach through technology can yield greater satisfaction and loyalty. Consistency in service aligns with overall business strategies, ensuring that the value of combi case erectors is maximized throughout their lifecycle.

Understanding Maintenance Costs: A Key Factor in Equipment Efficiency

In the realm of equipment efficiency, understanding maintenance costs is crucial for maximizing the effectiveness of combi case erectors. Maintenance costs not only directly impact operational budgets but also serve as a significant factor in overall equipment performance. As companies invest in advanced automation solutions, the ability to predict and manage these costs is essential for maintaining productivity levels and avoiding unexpected downtimes.

With the global market for automated material handling equipment projected to grow significantly, manufacturers must focus on strategies that enhance the longevity and efficiency of their assets. Regular assessments, predictive maintenance strategies, and investment in high-quality parts can mitigate excessive maintenance costs. Moreover, companies can leverage data analytics to monitor equipment health, allowing for timely interventions that prevent larger issues from arising. This proactive approach not only ensures smoother operations but also aligns with the industry's shift towards sustainability and cost-effectiveness in production environments.

Strategies for Reducing Repair Costs in Case Erector Operations

In modern packaging operations, reducing repair costs in case erector systems is a vital strategy for enhancing efficiency. Regular maintenance and timely inspections are critical. Implementing a proactive maintenance schedule not only helps in identifying potential issues early on but also extends the lifespan of your equipment, leading to fewer unexpected breakdowns.

Tip: Establish a routine check-up protocol that includes thorough inspections of all mechanical components, ensuring that wear and tear are addressed promptly. This will also minimize downtime and maintenance costs in the long run.

Additionally, investing in high-quality parts and components for your case erector can significantly impact repair expenses. Cheaper alternatives may save money initially but often lead to more frequent failures.

Tip: Work with reputable suppliers who offer warranties on their parts. This ensures that you're not only getting reliable products but also support in the event of malfunctions, contributing to lower overall repair costs.

By focusing on preventive measures and quality maintenance, businesses can streamline operations and minimize unplanned expenditures in their case erecting processes.

Evaluating the ROI of Superior After-Sales Support for Packaging Machinery

When investing in packaging machinery like combi case erectors, companies must consider not just the upfront costs but also the accompanying after-sales support, which can significantly influence ROI. A recent study by the Packaging Machinery Manufacturers Institute (PMMI) indicates that robust after-sales service can reduce machinery downtime by as much as 25%. This reduction is essential as downtime translates directly to lost revenue and wasted resources. Furthermore, companies that prioritize superior after-sales support report an average of 15% higher operational efficiency compared to those that don't.

Tip: Always evaluate the after-sales support package when purchasing machinery. Look for providers that offer comprehensive training, quick response times for service requests, and regular maintenance checks.

Enhanced after-sales support can also lead to improved employee morale. Equip your team with the knowledge and support they need to handle equipment properly. According to a report from the International Society for Pharmaceutical Engineering (ISPE), well-trained operators can enhance productivity by up to 20%. By selecting a supplier that offers exceptional after-sales training and support, you ensure that your workforce is highly skilled, ultimately maximizing the efficiency of your packaging operations.

Tip: Conduct regular training sessions with your team to keep everyone updated on new processes and technologies. This proactive approach can further secure your investment and yield greater returns.

Technical Training and Support: Enhancing Efficiency Through Expertise

In today’s fast-paced manufacturing environment, technical training and support play a crucial role in enhancing the efficiency of combi case erectors. When employees are well-versed in the machinery and its functionalities, they are better equipped to operate equipment effectively, minimizing downtime and maximizing output. Comprehensive training programs should encompass both foundational knowledge and hands-on experience, ensuring that team members can troubleshoot common issues and maintain optimal performance.

Furthermore, ongoing support from experienced technicians and engineers is essential for fostering a culture of continuous improvement. As technology evolves, staying updated on the latest advancements in combi case erecting solutions becomes vital. Regular workshops and training sessions can cultivate expertise, allowing teams to implement best practices and leverage new features that boost productivity. This synergy between training and support not only enhances operational efficiency but also contributes to employee satisfaction, as they feel empowered and confident in their skills.