Exploring 2025 Technological Advancements in Best Case Erectors for Global Buyers

As we look toward 2025, the landscape of technological advancements continues to evolve, significantly impacting various industrial sectors, including packaging and logistics. One of the key innovations in this realm is the Case Erector, a machine designed to streamline the process of assembling and erecting cardboard boxes for product packaging. This blog will explore the latest advancements in Case Erectors, focusing on features such as automation, efficiency, and sustainability that make them pivotal for global buyers. By examining the potential transformations in design and functionality, we aim to provide insights into how these technologies will enhance productivity and reduce costs in the ever-competitive marketplace. Join us on this journey to discover what the future holds for Case Erectors and their crucial role in shaping the packaging industry of tomorrow.

Impact of Chinese Innovation on Global Erector Technologies by 2025

As we approach 2025, the landscape of global erectors is poised for transformation, largely driven by China's innovative technological advancements. Chinese companies are leading the charge in adopting advanced automation and integrating artificial intelligence into their manufacturing processes. These developments are expected to significantly enhance the efficiency and precision of erecting structures, making them more robust and cost-effective for global buyers.

One of the most notable trends is the rise of 3D printing technologies, which have gained traction in the erector industry. The ability to create complex structures with minimized waste is a game-changer. As highlighted in the latest executive survey of industry leaders, the incorporation of additive manufacturing will not only streamline production but also foster creativity in design.

Tips for buyers looking to leverage these advancements include staying informed about the latest technologies and considering partnerships with innovative Chinese firms. Additionally, investing in training for skilled labor to operate these advanced systems will be crucial in maintaining a competitive edge. Embracing these changes will be vital for organizations aiming to thrive in the evolving global market.

Impact of Chinese Innovation on Global Erector Technologies by 2025

Emerging Trends in Erector Designs for Enhanced Efficiency in 2025

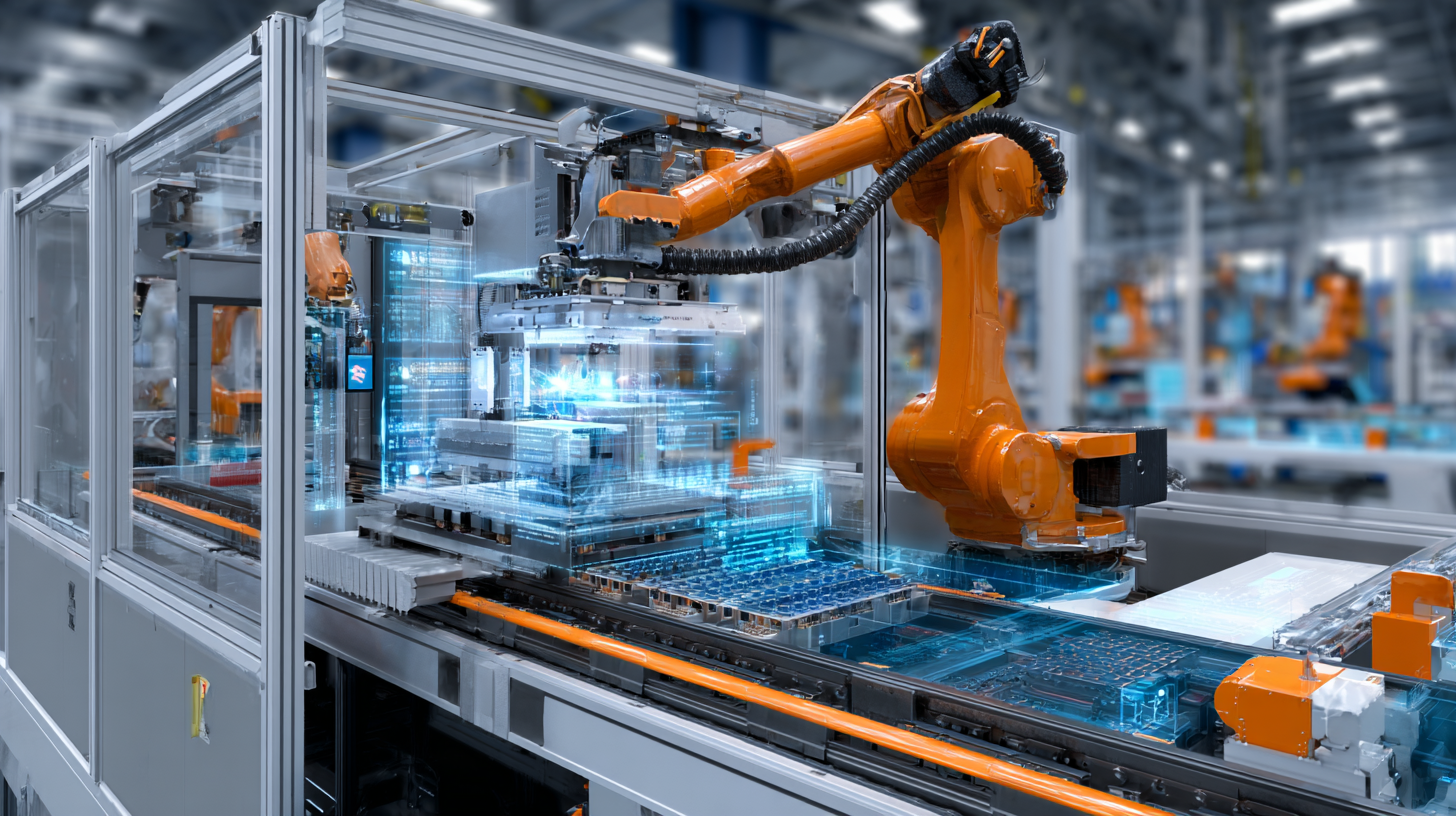

As we venture into 2025, the world of erecting technology is witnessing transformative trends that promise enhanced efficiency and productivity. One of the most notable advancements is the integration of automation and artificial intelligence in erector designs. By leveraging AI algorithms, these machines can analyze site conditions in real-time, allowing for adaptive erection processes that optimize resource allocation and minimize downtime. This shift not only streamlines assembly operations but also significantly reduces labor costs, making it a lucrative option for global buyers.

Another emerging trend is the move towards modular and sustainable materials in erecting technology. The construction industry is increasingly focused on reducing its carbon footprint, and new erecting designs utilize lightweight and recyclable materials that enhance structural integrity while promoting environmental responsibility. By adopting modular components, erectors can also facilitate faster assembly times and flexibility in construction layouts. This combination of sustainability and efficiency is key for global buyers looking for innovative solutions that align with their corporate responsibility goals. As these trends continue to evolve, we can expect the landscape of erecting technology to shift dramatically, presenting new opportunities for improvement in construction efficiency.

Quality Assurance: China's Secret to Winning Global Erector Markets

In the competitive global market for erecting technologies, China's emphasis on quality assurance has emerged as a key strategy for capturing international buyers. According to a report by MarketsandMarkets, the global erection equipment market is projected to reach $27.9 billion by 2025, with Asia-Pacific leading in demand. China's robust manufacturing sector, underscored by stringent quality control measures and adherence to international standards, positions it as a formidable player. Manufacturers are adopting advanced technologies such as IoT and AI to enhance precision and reliability, leading to higher quality outputs that meet global expectations.

Furthermore, China's commitment to continuous improvement in quality assurance practices is evident in the implementation of ISO certifications and participation in global quality standards. A survey conducted by Statista showed that 78% of global buyers prioritize quality assurance when selecting suppliers. By focusing on quality, Chinese firms not only ensure compliance but also foster trust with international partners. This focus allows them to not only meet but exceed industry benchmarks, making Chinese erected technologies highly competitive in a rapidly evolving market, thus solidifying their position as preferred suppliers in the global arena.

Sustainability in Erector Manufacturing: A 2025 Perspective

Sustainability is becoming increasingly crucial in the manufacturing sector, especially in the production of erectors. As we approach 2025, industry leaders are expected to adopt eco-friendly practices that minimize environmental impact while meeting global demand. Innovations such as the use of recycled materials and energy-efficient processes are at the forefront of this transformation, allowing manufacturers to reduce their carbon footprints substantially. Moreover, integrating renewable energy sources, like solar or wind, into the manufacturing cycle is anticipated to become standard practice, promoting a greener approach to erector production.

In addition to utilizing sustainable materials, the development of advanced technologies will play a significant role in enhancing efficiency throughout the supply chain. Automation and artificial intelligence can help optimize operational processes, thus decreasing waste while ensuring high quality. By embracing these advancements, erector manufacturers can not only contribute to a more sustainable industry but also meet the growing demand from global buyers for environmentally responsible products. As the market evolves, those who prioritize sustainability will likely gain a competitive edge, aligning with the values of conscientious consumers worldwide.

Future-Proofing Erector Technology: Integrating AI and Automation in 2025

As we look ahead to 2025, the integration of artificial intelligence (AI) and automation is poised to revolutionize the erector technology landscape. According to a recent report by MarketsandMarkets, the global construction robotics market is expected to reach $226.8 billion by 2025, showcasing a remarkable CAGR of 13.9%. This surge reflects the industry's increasing emphasis on efficiency and precision, particularly in the deployment of erector technologies. AI-driven solutions are enabling smarter project management, predictive maintenance, and enhanced safety measures on construction sites, thereby addressing some of the most pressing operational challenges faced by global buyers.

Automation, combined with AI, is not just transforming how structures are erected but is also leading to a paradigm shift in workforce dynamics. A McKinsey report indicates that up to 60% of all occupations could be automated by 2030, emphasizing the growing need for technology integration within the erector space. In 2025, we can expect erectors equipped with advanced robotics and machine learning algorithms that will streamline workflows, reduce labor costs, and minimize human error. This technology will empower builders to focus on higher-level decision-making, ultimately leading to faster project completions without compromising quality or safety standards.